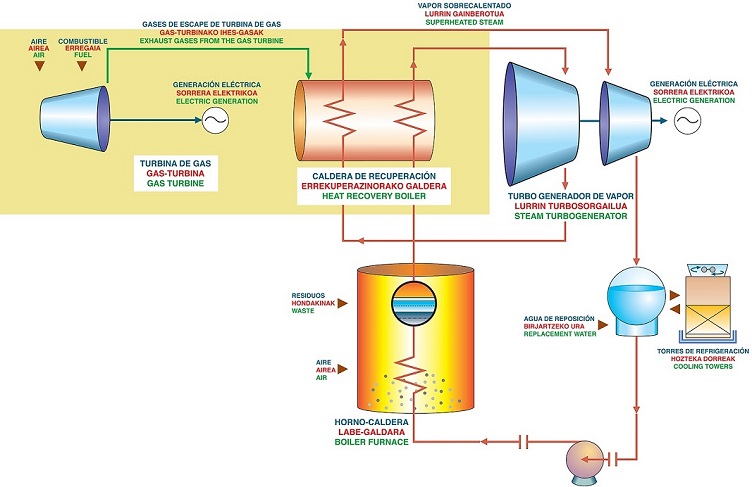

The Zabalgarbi or SENER urban waste-to-energy system is an industrial process that adapts the technology of combined-cycle gas plants to modern waste-to-energy facilities.

It is a single integrated process in which the facilities’ size and features are determined by the following:

- The plant’s required UW treatment capacity.

- Fine-tuning the thermo-electric performance.

- Reducing the environmental impact per kWh generated by the plant.

General process features

Saturated steam at a temperature of 310 °C and a pressure of 100 bar is produced in Zabalgarbi’s incineration-line furnace-boiler (30 tonnes/hour). This means less heat at a higher pressure than usually obtained in modern waste-to-energy plants (400 ºC at 35/40 bar).

This saturated steam from the furnace-boiler is superheated to 540 °C in a recovery boiler using heat from the flue gases of a 43 MW gas turbine, while maintaining pressure at 100 bar in conditions similar to those of a power plant using conventional fuels. The superheated steam is used to drive a 56.5 MW turbo-generator.

Gross power yield is 99.5 MW, and the net output after the plant’s own consumption is 94 MW.